Visual spot drill for glue and paint

作者:点胶机 日期:2020-08-17 20:28 浏览:

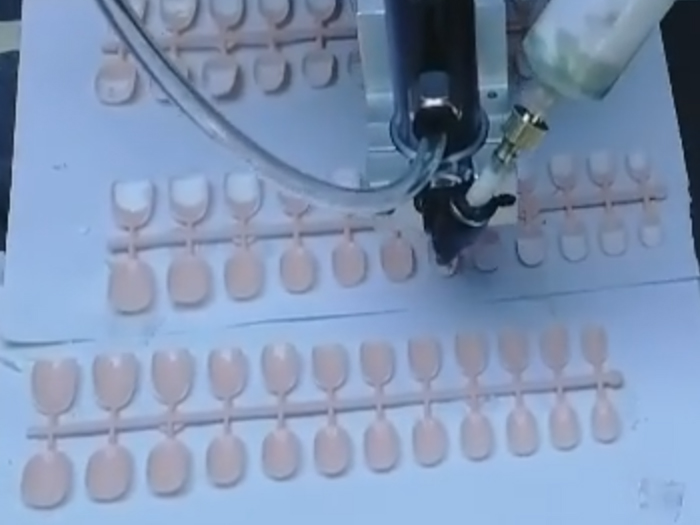

Generally speaking, there is a high demand for the spot painting process, and the demand is also quite large. Using the ordinary painting technology every day has high cost, long time consumption and relatively high expenditure cost, which does not meet the core needs of the manufacturer. Our company has developed a machine, which is specially used for dispensing and dispensing paint, with visual system, which can quickly and accurately complete the task of painting. This is the dispensing and dispensing drilling rig, floor type structure , large working platform, no need to discharge products, machine can identify.

Characteristics of glue and paint dispensing drill

1. The working platform has 500 * 500 * 100, no need to use fixture, as long as the product can be placed on the work plane.

2. Intelligent, can automatically identify the product dispensing position, accurate dispensing.

3. Spray dispensing can finish 250 dispensing points in one minute. It is fast, accurate and stable. It is the preferred equipment for painting effect.

4. Motor selection effect is better, with high speed and no noise motor, servo motor stability is strong, high accuracy.

5. It has the function of automatic detection. If the painting effect is not enough, the paint will be repaired automatically.

6. Support a variety of dispensing requirements, the control effect is really good.

Scope of application

In fact, many industries can use, such as: signs, car logo, jewelry, diamonds, chips, watches, hardware, etc., need to use the spray painting technology, but the products with high precision demand can still be used, the effect is very good, the use is convenient, the design program is also very simple, PLC control system, independent programming system, strong stability, after-sales service No worries.

The machine is a comprehensive dispensing equipment, which also symbolizes the further expansion of the dispensing field. The visual dispenser can solve the problem of glue spraying, meet the quality requirements of products, solve the production problems, and expand the production line. One machine can hold five or six people, and can access more orders!