The importance of maintenance to the large LED packaging dis

作者:马交易 日期:2018-02-09 11:08 浏览:

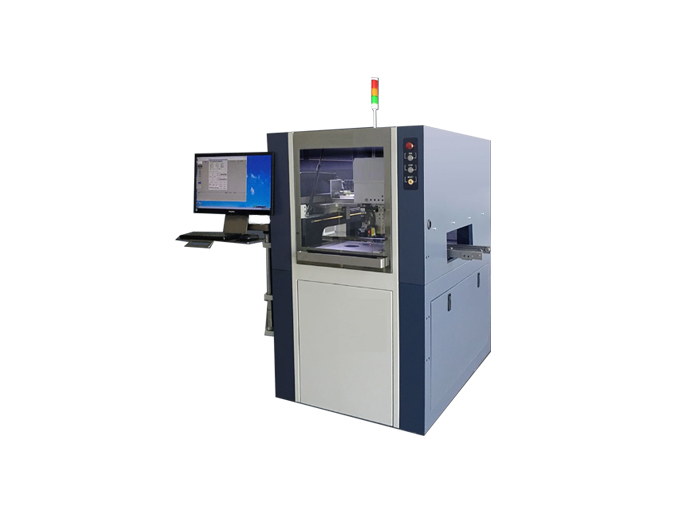

Large LED package dispensing machine is mainly used in the chip package link lights, LED lights will be placed on the chip material, using silica gel and fluorescent powder was coated on the surface of the chip package, the package after the LED light material that is normal lighting, but also to protect the core work, so large LED package dispensing machine in the industry production plays a decisive role, LED package dispensing machine maintenance work is particularly important, the operator should know for maintenance procedures LED package dispenser.

The dispensing cleaning input is associated with the usual maintenance, daily maintenance work of cleaning can save a large amount of investment, after the completion of the work should be dispensing glue and then separately removed from the glue dispensing valve, avoid too long not used in the internal curing. The working guide of large scale packaging and precise dispensing machine for energy-saving lamps needs to ensure that there is no dust accumulation inside the body to play a more fluent work effect. Operators should regularly remove dust accumulated in mobile guideway, so as to enhance the quality of LED packaging dispensing machine.

If there is no need for further dispensing, the operator should turn off the power in time to avoid the long run and affect the service life of the equipment. If there is residual glue on the dispensing platform, it should be removed in time, so as to avoid affecting the consistency and smoothness of dispensing.

For large cleaning process LED package dispensing machine, it is best to avoid using cleaning agent cleaning erosion is strong, easy to affect the dispensing dispensing accuracy and dispensing quality, can use acetone soaked cleaning dispensing valve and dispensing needles and other parts, can effectively remove foreign debris attached to the parts.