It is better to choose which glue machine to use chip to spo

作者:马交易 日期:2018-02-06 17:33 浏览:

General chips will be assembled in the motherboard, and chips can be used as the core components of the main board. During the assembly process, the dispensing machine chip industry will be dispensed automatically, but there are many kinds of dispensing machines, such as fast dispensing, high dispensing and high density. So you can use those automatic glue dispensers in the chip industry?

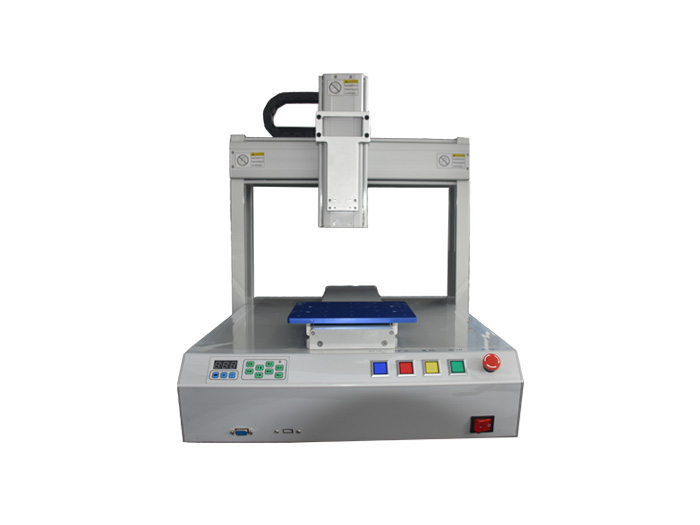

One, three axis automatic glue dispenser

It can be seen from the name that the three - axis automatic dispensing machine is equipped with three spot glue valves or three slideways. The glue can be used at the same time, and the efficiency of the glue is high. It can work in three directions of X, Y and Z. The amount of dispensing is not uniform. Before using the three axle dispensing machine to do the dispensing, it is necessary to choose the appropriate inner diameter size dispensing needles according to the requirements of the chip, so that the product quality is not suitable for dispensing.

Two. A desktop automatic glue dispenser

Desktop automatic glue machine can also be called the desktop glue machine, the general desktop type of glue machine model is relatively small, it is more convenient to place. It can realize irregular graphics such as line, circle, arc and so on. It can meet the needs of different industries. Desktop automatic dispensing machine can not only be used in the chip industry, but also can be used in the electronic parts, cell phone buttons, medical devices, LED display and other industries. =

Three. High speed automatic glue dispenser

General automatic dispensing machine is based on the control system to do glue work, and high speed automatic glue dispenser is the same. In order to operate conveniently, the controller is installed in the high speed glue machine. After the power is opened, the staff can manually adjust the parameters of the glue. It is convenient to use. And the speed of the high speed glue dispenser is faster, the precision is higher, and the quality of the chip can be guaranteed during the dispensing process.