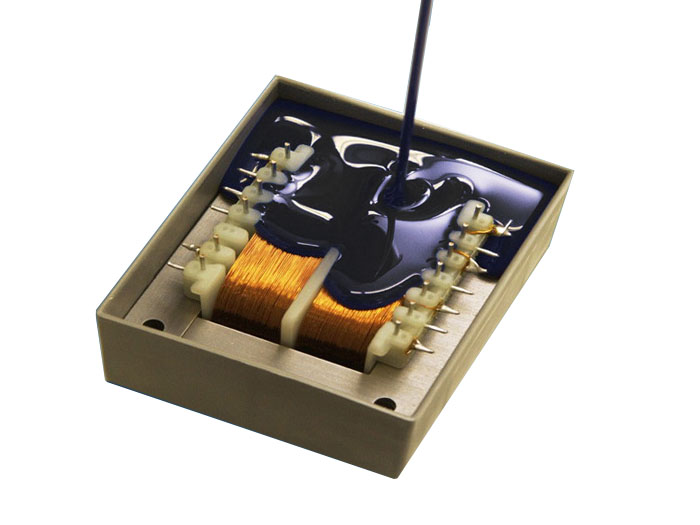

Magnetic core bonding

作者:点胶机 日期:2020-07-06 17:39 浏览:

The magnetic core bonding is potted with epoxy resin adhesive. Covering the whole core can protect the magnetic core from external factors. It is moisture-proof, waterproof, discharge, insulation and so on. It is protected by glue. Many products will use epoxy resin glue or potting glue as core glue, which has a long service life. The general environment has no influence on the glue.

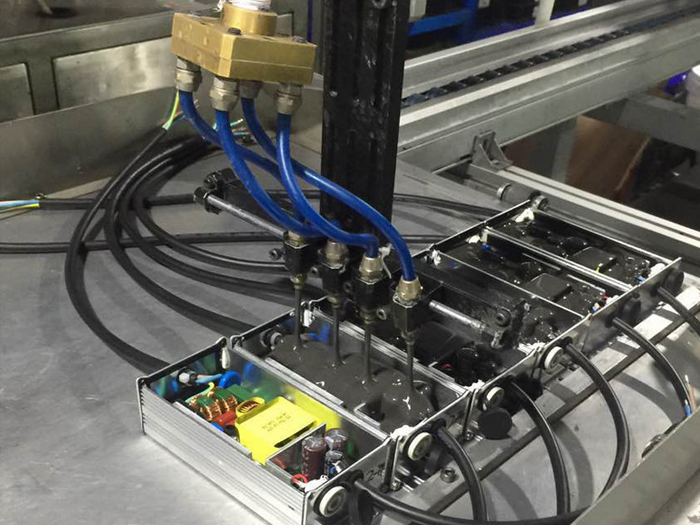

At present, there are two types of epoxy resin dispensing machine, floor type and table type. According to the requirements of magnetic core bonding, the manufacturer can choose the most suitable machine according to the introduction of our company. In fact, the requirements of single component epoxy resin glue pouring are not very high. The table type and floor type can meet the requirements. The glue has no bubbles and no bubbles Mixed requirements, for machine technology requirements, will be much lower.

Capacitor filling will use two-component potting glue with a mixing ratio of 5:1. Many accessories need to be added to the pouring machine, such as dynamic filling valve, defoaming pump, metering pump, etc. These are the configuration that needs to be added, which is much more difficult than the use of single component. As a result, the price of the pouring machine is much higher than that of the epoxy resin dispenser. The price of a floor mounted dispenser is much higher than that of the epoxy resin dispenser It's about 80000. The higher the precision of glue filling device is, the higher the price will be.

Capacitor glue filling and magnetic core bonding are the same principle. They are both covered type, but the glue used and production mode are different. The epoxy resin dispensing machine and pouring machine have the same effect. According to the core needs of your company, you can choose the appropriate style to meet the glue filling demand, and the quality will be guaranteed.