SZ CnAuto automation equipment Co., Ltd.

快盈v3Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

快盈v3Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

TEL:

18929475867

快盈v3

Email:jerry@prcrobot.net

QQ:a href="http://wpa.qq.com/msgrd?v=3&uin=88965272&site=qq&menu=yes":

快盈v3ADD:东莞市塘厦镇石潭浦大迳路62号

作者:马交易 日期:2019-11-09 15:46 浏览:

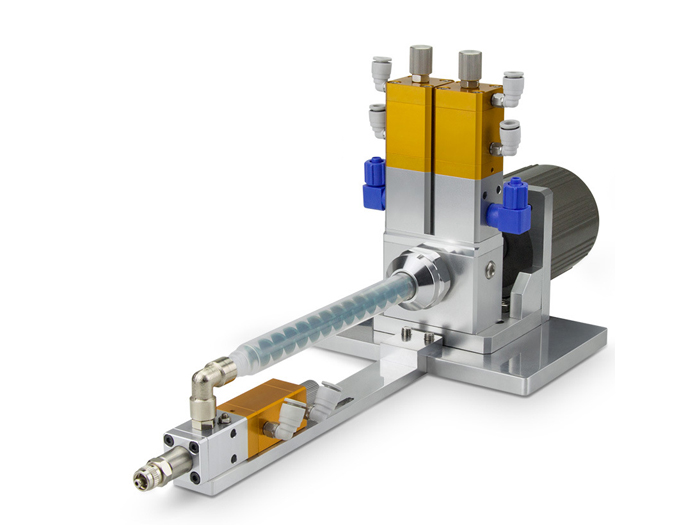

In fact, the installation method of glue filling valve is very simple. Let's first understand what kind of glue filling valve there are. In large part, it can be divided into two types. One is electric and the other is electric. According to the applicable glue, it can be divided into two liquid and single liquid glue filling valves. In addition, it can be classified according to the viscosity of the glue used.

In fact, the installation method of glue filling valve is very simple. Let's first understand what kind of glue filling valve there are. In large part, it can be divided into two types. One is electric and the other is electric. According to the applicable glue, it can be divided into two liquid and single liquid glue filling valves. In addition, it can be classified according to the viscosity of the glue used. However, for a single glue filling valve, only one glue can be used. In fact, it doesn't matter which kind of glue filling valve your products need. For a glue like silica gel, only one glue filling valve can be used to seal silica gel. For a glue like AB mixed glue, a double glue filling valve is needed.

However, for a single glue filling valve, only one glue can be used. In fact, it doesn't matter which kind of glue filling valve your products need. For a glue like silica gel, only one glue filling valve can be used to seal silica gel. For a glue like AB mixed glue, a double glue filling valve is needed.