Effect of Jet Dispenser on Different Rubber Requirements

作者:点胶机发布员 日期:2019-11-02 10:28 浏览:

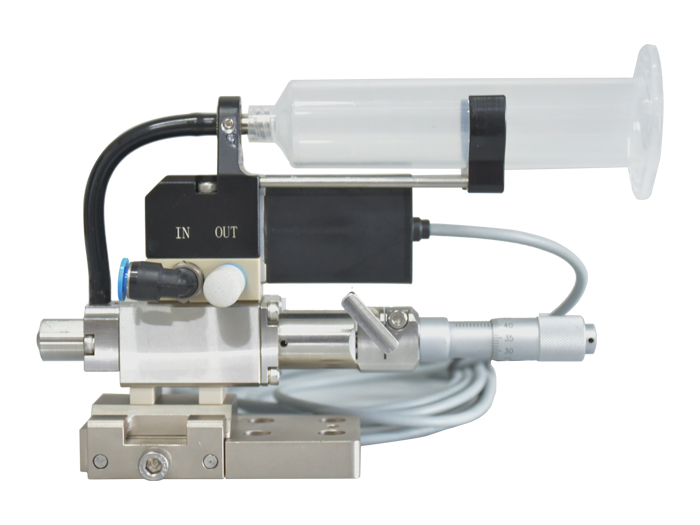

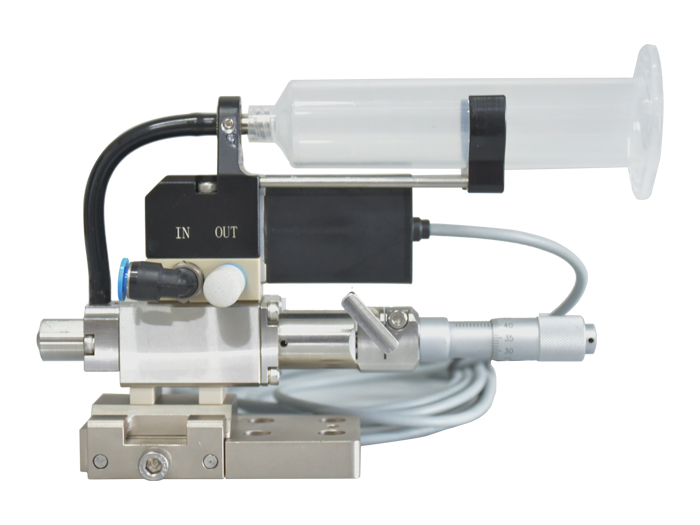

What is the requirement of spray dispenser for rubber? In fact, dispensing machine and glue can not be separated, the quality of glue will affect the dispensing effect of jet dispensing machine to a certain extent, so no matter what type of jet dispensing machine has its dispensing material requirements.

In addition to the influence of glue and external environment, the dispensing machine used by enterprises usually uses a screw pump to supply dispensing needle delivery, so constant pressure is needed to ensure that enough glue is supplied to the screw pump. If the pressure is too high, the glue will overflow, and then the amount of glue will be too large, otherwise if the pressure is too small. There will be intermittent distribution and leakage resulting in defects, which to a certain extent are affected by the rubber, so there are different requirements for dispensing compound.

Therefore, the pressure of spray dispensing machine should be selected according to the working environment temperature of different glue and spray dispensing machine of the same quality. High temperature will reduce the viscosity of glue and improve its fluidity. In this case, the supply of glue can be ensured by reducing back pressure, and vice versa.

The dispensing quantity of spray dispensing machine depends on the working experience. The diameter of the adhesive spot should be half of the distance between the pads. Of course, it is also related to the properties of the glue. Therefore, it is necessary to meet the requirements of dispensing glue. The diameter of the glue spot after pasting should be 1.5 times of the diameter of the glue spot. This ensures that there is enough glue to bond parts and prevent excessive glue filling. The amount of glue coating depends on the rotating time of the screw pump. In fact, the rotating time of the pump should be selected according to room temperature and glue viscosity.

Jet dispensing machine manufacturers believe that the correct and rational use of dispensing machine can greatly improve the dispensing efficiency, improve the quality of dispensing by reducing the rate of defective products, avoid useless waste of glue, in order to meet the requirements of dispensing materials to use so that it can achieve high dispensing effect.