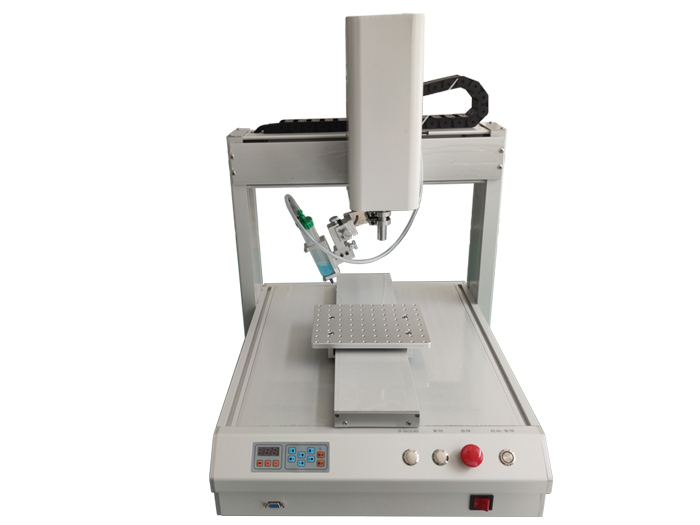

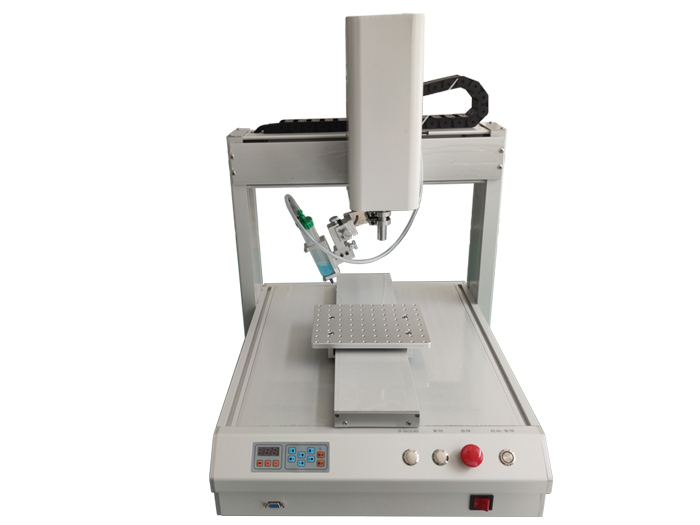

Some common problems in automatic dispensing equipment

作者:马交易 日期:2019-08-14 21:02 浏览:

1 glue volume

According to working experience, the problem of dispensing equipment is mainly related to the amount of glue. The diameter of the adhesive spot should be half of the distance between the pads, and the diameter of the adhesive spot after patching should be 1.5 times of the diameter of the adhesive spot. This ensures that there is enough glue to bond components and avoid excessive glue immersion in the pad. The amount of glue dispensing is determined by the rotating length of the screw pump. In practice, the rotating time of the pump should be selected according to the production conditions (room temperature, glue viscosity, etc.).

2 dispensing pressure (back pressure)

The current dispensing equipment uses a screw pump to supply pressure for the hose of dispensing needle to ensure that there is enough glue to supply the screw pump. If the back pressure is too high, the glue will overflow and the glue volume will be too much. If the pressure is too low, intermittent dispensing or leakage will occur, which is the defect caused by dispensing equipment problems. Pressure should be selected according to the same quality of glue and working environment temperature. When the ambient temperature is high, the viscosity of the glue decreases and its fluidity improves. Back pressure is needed to ensure the glue supply, and vice versa.

3-point glue needle size

In practical work, the inner diameter of the needle should be 1/2 of the adhesive point diameter. In the dispensing process, dispensing needle should be selected according to the size of PCB pad. If the size of pad is not different between 0805 and 1206, the same type of dispensing needle can be selected. However, different needles should be selected for different gaskets, which can ensure the quality of dispensing gel and improve production efficiency.

The distance between 4 pins and PCB board; different distributors use different pins, and some pins have a certain degree of stopping (e.g. CAM/A LOT 5000). The distance between needle and PCB should be calibrated at the beginning of each dispensing, i.e. Z-axis height calibration.

5 glue temperature

General epoxy resin glue should be stored in 0 - 5 degree C refrigerator, should be removed half an hour in advance, so that the glue and glue work at the same temperature. The temperature of the glue should be 23 C - 25 C, and the ambient temperature has a great influence on the viscosity of the glue. When the temperature is too low, the adhesive point decreases and the tensile phenomenon occurs.

The difference of ambient temperature of 5 C will lead to 50% change of distribution. Therefore, environmental temperature should be controlled. At the same time, environmental temperature should be guaranteed. Small adhesive point is easy to dry and affects adhesion, which is also one of the problems of dispensing equipment.

6. Viscosity of glue; Viscosity of glue directly affects the quality of glue. If the viscosity is high, the glue point will become smaller or even stretch, the viscosity will be very small, the glue point will become larger, and the pad may infiltrate. In the process of distribution, reasonable back pressure and distribution speed should be selected for glue with different viscosities.

7 bubbles

No bubbles in glue. Small gases can lead to many gaskets without glue; every time the hose is replaced in the middle, the air at the joint should be emptied to prevent runaway. For the adjustment of the above parameters, the change of any parameter will affect other aspects, and may cause defects in many aspects, and check the possible factors one by one. Exclude. In short, the parameters should be adjusted according to the actual situation in production, which not only ensures the quality of production, but also improves the production efficiency.

2 dispensing pressure (back pressure)

2 dispensing pressure (back pressure) The distance between 4 pins and PCB board; different distributors use different pins, and some pins have a certain degree of stopping (e.g. CAM/A LOT 5000). The distance between needle and PCB should be calibrated at the beginning of each dispensing, i.e. Z-axis height calibration.

The distance between 4 pins and PCB board; different distributors use different pins, and some pins have a certain degree of stopping (e.g. CAM/A LOT 5000). The distance between needle and PCB should be calibrated at the beginning of each dispensing, i.e. Z-axis height calibration.