SZ CnAuto automation equipment Co., Ltd.

快盈v3Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

快盈v318929475867

快盈v3Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

快盈v318929475867

TEL:

18929475867

快盈v3

Email:jerry@prcrobot.net

QQ:a href="http://wpa.qq.com/msgrd?v=3&uin=88965272&site=qq&menu=yes":

ADD:东莞市塘厦镇石潭浦大迳路62号

作者:吴交易 日期:2019-07-01 21:00 浏览:

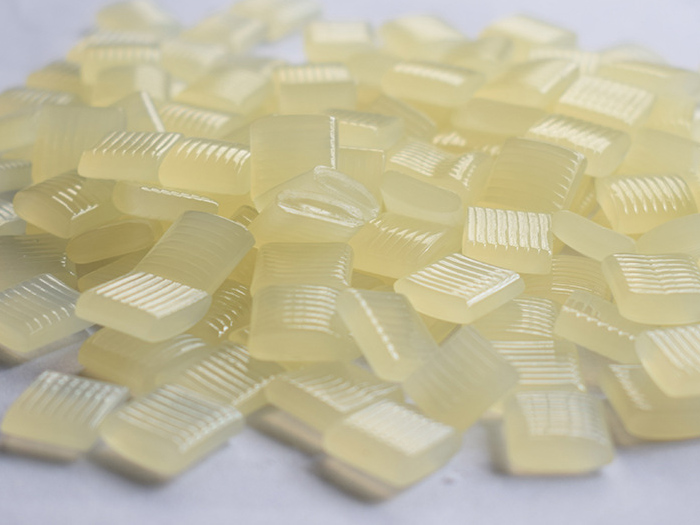

The perfume bottles are dispensed with hot melt adhesive, and then heated according to the requirements of hot melt adhesive, so that the dispensing can be realized. On the automatic dispensing machine, the temperature heating device and the constant temperature system will be added. The hot-melt adhesive can be heated in advance, then the perfume bottle will be dispensed. At present, hot melt adhesive is basically used in this way, and the dispensing accessories are dispensed according to the characteristics of the glue, which is an automatic point. The glue machine is operated by conventional methods.

The perfume bottles are dispensed with hot melt adhesive, and then heated according to the requirements of hot melt adhesive, so that the dispensing can be realized. On the automatic dispensing machine, the temperature heating device and the constant temperature system will be added. The hot-melt adhesive can be heated in advance, then the perfume bottle will be dispensed. At present, hot melt adhesive is basically used in this way, and the dispensing accessories are dispensed according to the characteristics of the glue, which is an automatic point. The glue machine is operated by conventional methods. Core accessories of hot melt dispenser

Core accessories of hot melt dispenser

The automatic gluing and bonding technology of automatic dispensing machine has blossomed in all walks of life, and now the production cost is high, it is difficult to survive in the market without increasing the production speed. Therefore, the machine production has become a new way out. Although the first cost is high, it only takes three months to return the cost, and the production of automatic dispensing machine is still comparatively advantageous.

The automatic gluing and bonding technology of automatic dispensing machine has blossomed in all walks of life, and now the production cost is high, it is difficult to survive in the market without increasing the production speed. Therefore, the machine production has become a new way out. Although the first cost is high, it only takes three months to return the cost, and the production of automatic dispensing machine is still comparatively advantageous.