How to prevent problems in the working process of multi axis

作者:马交易 日期:2018-02-06 17:38 浏览:

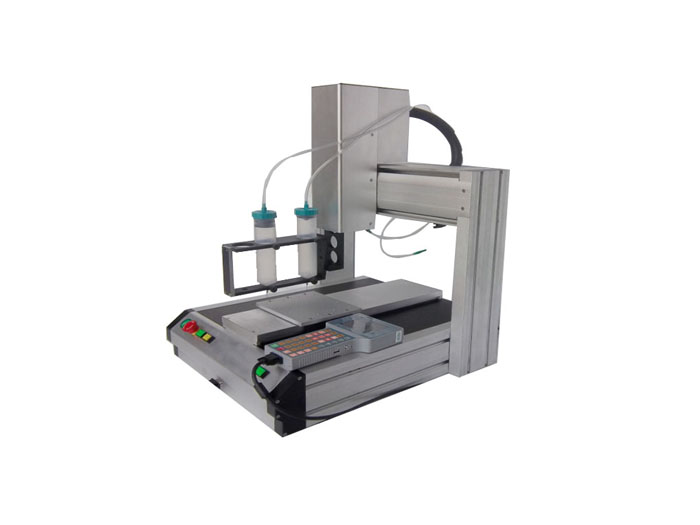

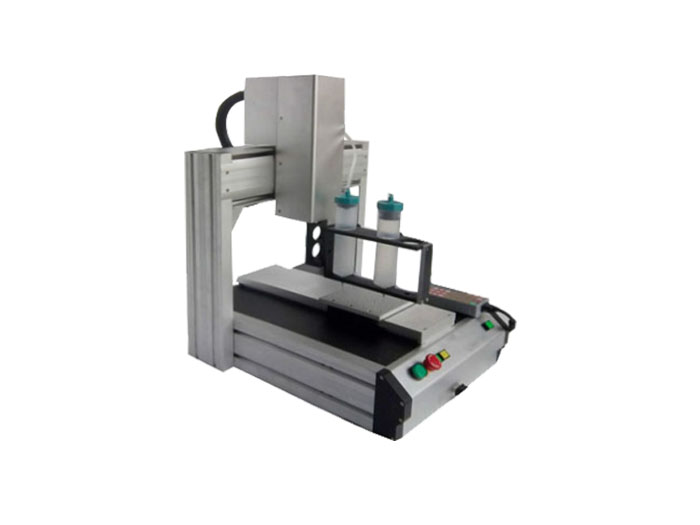

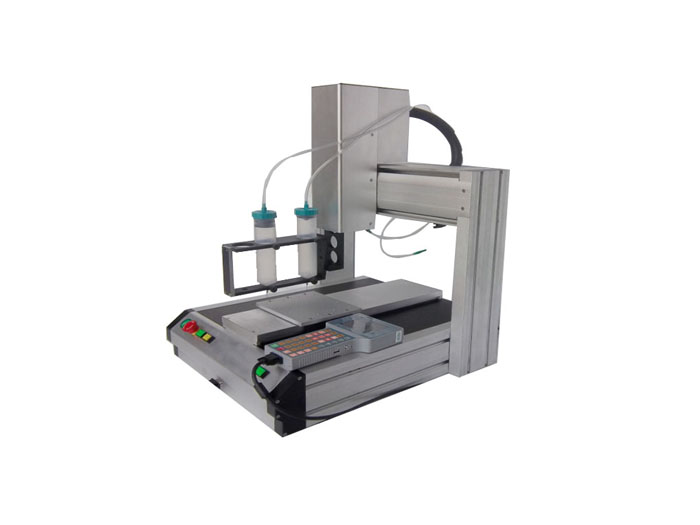

With the application of dispensing technology, more and more industries need to strengthen the value of products through the dispensing, multi axis dispensing machine is responsible for bonding, in the manufacturing industry in the production of sealing glue, etc., for the manufacturing industry production, need to ensure the steady function of multi axis dispenser for dispensing can enhance the production efficiency, so as to improve the the stability is relatively more important, how to prevent the multi axis dispensing problems at work?

Multi axis dispensing machine is mainly embodied in the control is not precise enough glue dispensing problems in the battery box, the battery box is of compact structure, high work precision dispensing equipment, if you choose the ordinary glue dispensing needle prone to excessive overflow problems, so the multi axis dispensing machine should choose suitable dispensing needle such as high precision, high precision dispensing needles, needles to reduce the pump working pressure, the conveying effect of glue has been further enhanced, and prolong the service life of the multi axis dispensing machine, effectively prevent the dispensing process drawing and blockage problems, suitable for many kinds of glue supply demand for smaller products.

One of the battery compartment pressure barrel is multi axis multi axis dispensing machine accessories, dispensing machines often appear in the actual application of glue supply is not stable, or other problems caused by leakage defect product dispensing, can be connected as a storage barrel stainless steel pressure glue device in multi axis dispensing machine, stainless steel barrel has good anti pressure the erosion ability, make the transmission more stable and efficient glue effect, avoid glue supply caused by uneven glue leakage problems.