What are the problems that have not been made according to t

作者:马交易 日期:2017-12-27 09:22 浏览:

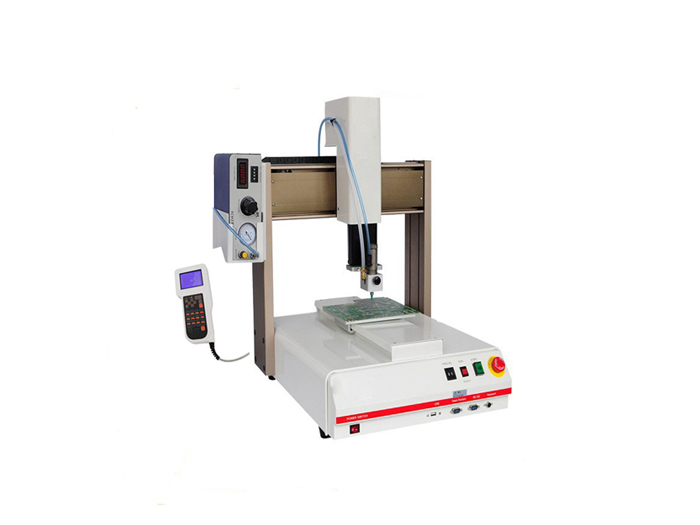

In the process of application of high speed jet dispensing machine, the glue must not have a bubble, a little stingy will form many pads without glue, glue to spray out of the situation, the emergence of a large number of bad products, so in each change necessary hose at the junction of emptying bubbles. On curing glue, usually manufacturers will give temperature curve. In the actual operation as far as possible to use a lower temperature to solidify, so that the glue solidified after enough strength. Then, the application of spray type automatic glue machine operation attention? Below is a simple introduction to the users.

In the process of using the high speed injection type glue dispenser, the problem will be caused by various reasons. For example: epoxy, the sealing problem caused by glue curing, and curing the bubble. These conditions often perplex the application manufacturers. Therefore, when choosing high-speed dispensing machine, do not only care about the high cost of purchase. As the saying goes, "a penny and a piece of goods", we must choose a high speed sprayed dispenser with good reputation.

The situation is causing the most glue seal problem, because the price is cheaper, the quality of dispensing machine is also a serious problem, leading to a design flaw or the durable. Tight seal, material bucket and pipeline and other aspects, seemingly complex pipelines, specific glue to select a special feeding tube and so on.

There are usually two reasons for the poor curing, one, the precision of the proportion of glue is not enough. Two, the mixing effect is not good. Therefore, the precision of the metering pump is very important. There are two ways of static and static mixing. As for which way to choose, it should also be determined according to the practical nature of glue.