Polyurethane sealant for household appliances

作者:点胶机 日期:2020-08-06 14:38 浏览:

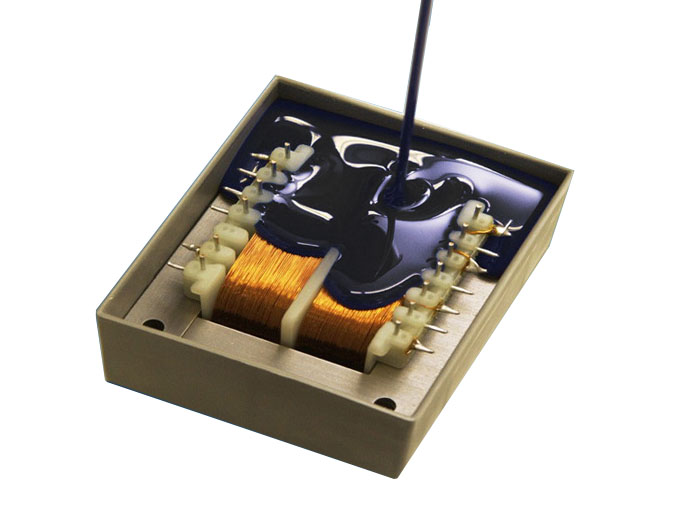

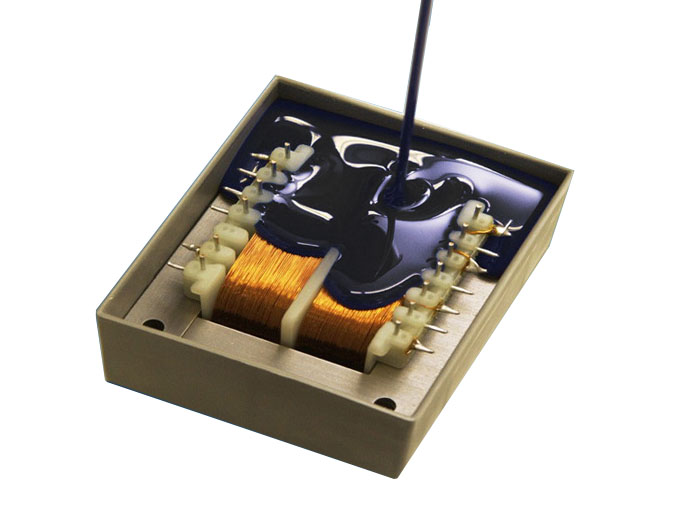

Many products in the domestic market need to be sprayed, sealed, glued and glued. In order to improve the product stability, the product bonding effect will greatly affect the product practicability, such as: household appliances using polyurethane filling, enhance the strength and electrical effect of electrical appliances, reduce energy consumption, but also has a certain degree of heat conductivity, reduce the degree of heating of electrical appliances, use polyurethane fillingThere are many glue effects, let's know the electrical effect of polyurethane glue.

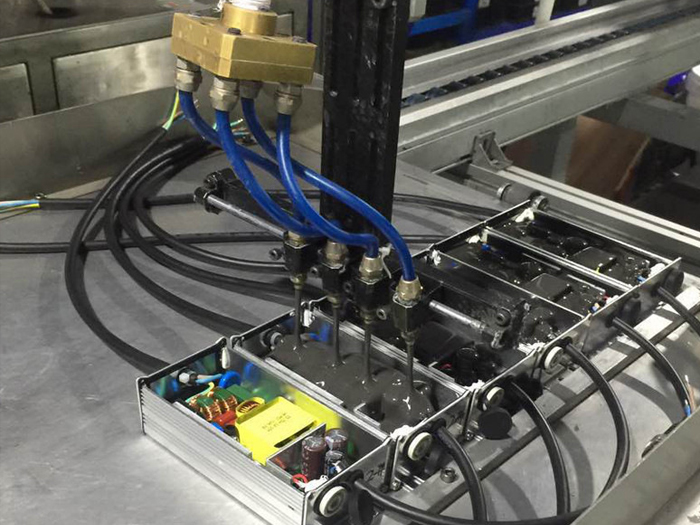

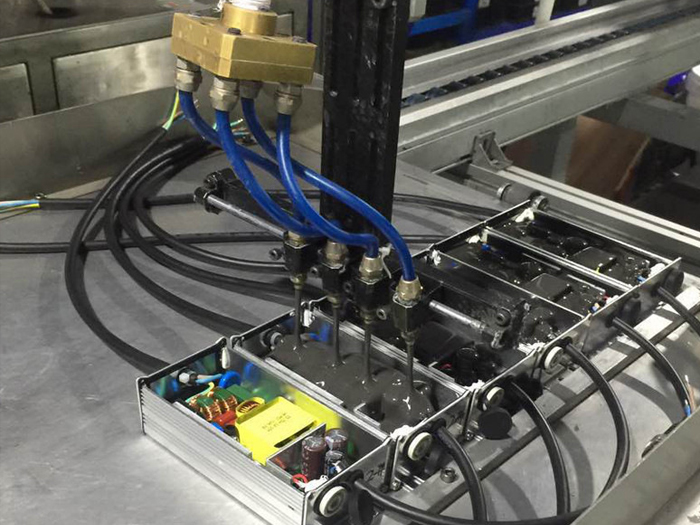

Polyurethane glue is a two-component glue with a mixing ratio of 3:1 to 5:1. It can be used with polyurethane glue, usually with resin glue seamer. This is a floor glue filling device with large size. It can install a variety of glue filling devices, such as vacuum defoaming device, metering pump, 20-liter pressure barrel, electric stirring point glue valve and large working platform. It uses a PLC programming controller with contacts.Touch screen, stable system, simple control, hand-held teaching, half-hour familiarity with operation, increasing degree of automation, operation requirements are decreasing, which is the advantage of the development of modern technology.

In addition to the polyurethane glue used for home appliances, mobile phone quick filling glue and hardware mould glue will also be used, of which the most widely used is LED power filling, because polyurethane glue has good insulation and thermal conductivity, LED power is easy to heat up, use other glue, for low safety, polyurethane glue is developed to meet the needs of electrical appliances.For glue demand, electrical appliances use for insulation requirements or high, leakage, for people is extremely dangerous, if there is insulation effect, can avoid electric shock, glue and heat conduction effect, to protect electrical appliances from overheating and burning products.

The glue filling effect of hardware moulds mainly depends on what machine is used. If you have time, you can send some samples to my company.Then proofing your company, use the resin glue seaming machine produced by us to see if the effect and speed can meet the requirements, because we have sample proofing, so you can see the effect of product glue after, rather than how, quick filling glue is also the same, the effect is only known after the sample, because the effect of each product requirements may beDifferent, so we still take each company's requirements as a constant standard, and the same is true in polyurethane gel appliances.