What should be paid attention to when using jet automatic di

作者:马交易 日期:2017-11-20 10:51 浏览:

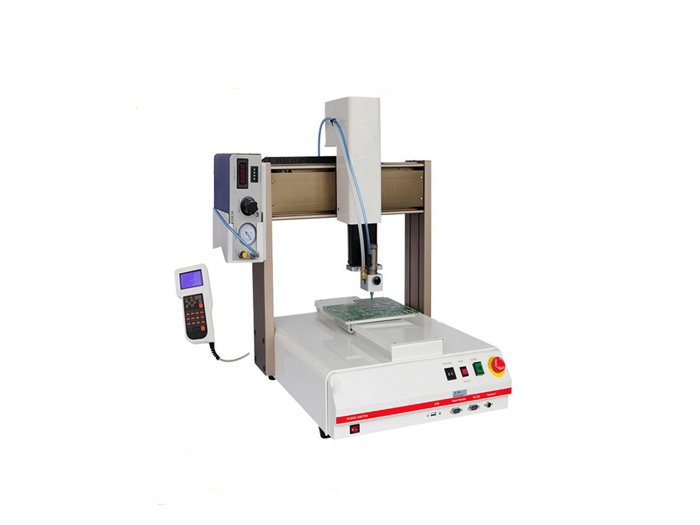

Application of spray type package more automatic dispensing machine in each production industry, can quickly and accurately will glue to point to spray the surface of objects, through the automatic dispensing system can quickly use the glue dispensing work items, after treatment, the conversion rate of high energy saving, by spraying the product after beautiful and flawless, is a a very strong practical equipment in the normal dispensing process need to pay attention to some problems in order to better finish the work.

Through the injection valve after the treatment will not affect the normal use of glue viscosity, some operators initial operation may cause excessive spraying, so the operation personnel in the operation of injection type automatic dispensing machine before you set the most accurate adhesive strength, such as spray pressure, spray speed, glue nozzle size parameters avoid excessive glue stick to the other place to affect the normal work. In order to prevent the high viscosity glue for automatic glue stick in the body, before the work of operators prepare the corresponding protective measures.

Power injection type automatic dispensing machine provides the best way to choose large power motor, check whether the normal work of the best servo motor in the normal work before, and check whether the dispensing work through the normal working voltage stability, voltage regulator stable dispensing space.

Due to the long-term implementation of strong spray work, large jet automatic dispensing machine work burden, so to conduct regular maintenance of equipment to better complete dispensing work, easily clean cleaning equipment to reduce investment, there is found the spray head residue to dispose of, if there is dust around the automatic dispensing machine body you can easily remove.